Authors:

Matt Clark, UMN Assistant Professor and Extension Specialist, Grape Breeding and Enology

Leslie Holland, UW-Madison Assistant Professor and Extension Specialist, Fruit Pathology

Annie Klodd, UMN Extension – Fruit Production

If downy mildew and powdery mildew are present on grapevine leaves at harvest, control measures should be considered at that time to prevent early leaf drop and help vines properly acclimate for winter.

Post-harvest vineyard management of downy and powdery mildew is critical as these diseases can appear late in the season and reduce photosynthesis, defoliate vines, and increase the risk of winter damage. Vineyard managers should scout early and often, and continue to control for these diseases late into the season.

Furthermore, control now can have a major impact on the disease pressure in the following year due to the reduction of overwintering fungal structures. Vines that are stressed in the fall are also more likely to suffer winter damage.

Fungal (and fungal-like) pathogens are commonplace in vineyards throughout the state. Infections of downy mildew (Plasmopora viticola), black rot (Guignardia bidwellii), and powdery mildew (Uncinula necator) are perennial problems in the region, but can have devastating effects when environmental conditions are favorable to their growth and dispersal.

Although powdery mildew favors ‘dry’ conditions, its dispersal depends on rain events and wet leaf surfaces to create infection sites. Downy mildew is favored by humid conditions.

Late-season control of downy mildew and powdery mildew

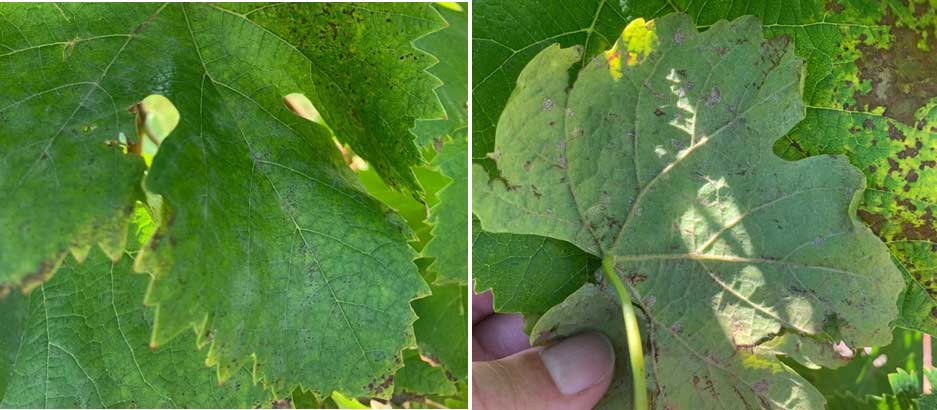

First, make sure you have correctly identified the disease so that you apply the right fungicides that are effective on that disease. If necessary, send a sample to the UMN Plant Disease Clinic. On leaves, powdery mildew sporulation is typically on the upper surface, whereas downy mildew is predominant on the lower surface where it establishes in the stomata. Both pathogens can cause damage on shoots, petioles, and rachises (the branches of the cluster), especially in fall.

There are many fungicides available for control of downy mildew and powdery mildew, but the lists of recommended products are not identical for both diseases. Consult the Midwest Fruit Pest Management Guide (MFPM) for the latest recommendations of fungicides for the control of powdery mildew and downy mildew on grape.

To select which fungicide(s) to apply during or after harvest, consider what you have already applied, and which products will work best on existing infections. Many products have limits on the number of applications each season; check label for season limits. If you have already reached this limit for a product you are considering, select a different product with a different FRAC code (described below) to reduce the risk for fungicide resistance.

Below are examples of possible options for control of downy mildew and powdery mildew. This is not an exhaustive list. Please consult the MFPM Guide for additional options and recommendations for your spray program. Always consult the fungicide label before making any applications.

Downy Mildew

- Protectants: Captan (FRAC M4) and Mancozeb (FRAC M3)

- Excellent control: Forum (FRAC 40) and Zampro (FRAC 40 + 45)

- Post-infection: Phosphorus acids (FRAC 33). According to Michigan State University, phosphorus acid is a common option for late season applications.

Powdery Mildew

- JMS stylet oil

- Excellent control: Quintec (FRAC 13) and Torino (FRAC U6)

If you still have fruit to harvest, pay close attention to the pre-harvest interval (PHI) on the product label as this will limit the products available to you for disease control. The PHI is the minimum amount of time (days) between application and harvest that is acceptable. For example, phosphorus acid, Captan, and copper have 0-day PHIs, while many strobilurins have 14-day PHIs.

Fungicides applied post-infection can help prevent the spread of the disease to healthy plant tissues and suppress sporulation of the pathogen. It’s best to make applications when you first observe the signs of infection, as disease control becomes more challenging the longer you wait. Applications of fungicides for post-harvest management on grape should not be used to eradicate extensive infections that are widespread and heavily sporulating as this can lead to resistance. Applications should be made during good spray conditions (consult the fungicide label for details) and avoid making applications when spray conditions are not good.

What rate to use: Rates are listed in the MFPM guide as well as the product labels. Always refer to the label before spraying. The same rates apply for post-harvest and pre-harvest applications.

Effective disease control is a season-long project

Most of the common grape diseases can be controlled with interventions early in the year from pre-bloom through bloom. Properly timed fungicide applications and cultural methods that improve air circulation and leaf drying will help prevent infections.

Some cultivars are more susceptible to these fungal pathogens than others. For example, ‘La Crescent’ often can have significant leaf infections of downy mildew but will not demonstrate fruit infections on the same vines. In general, as fruit develop, they become less susceptible to the fungal pathogens because their tissues have become less hospitable for harboring an infection site, something termed ontologic resistance.

Cultural control and fungicide applications should persist through the growing season, and growers can turn to the Midwest Fruit Pest Management Guide 2019-2020 for information on the best practices for controlling these and other pests. This booklet is the ultimate guide for growers across the region and is updated every two years by a team of university fruit specialists called the Midwest Fruit Workers Group.

Preventing Fungicide Resistance

Both the downy mildew pathogen and the powdery mildew pathogen are especially prone to fungicide resistance. The development of resistance to fungicides is problematic and is related to the over use (repeated use) of the same fungicide or fungicides with the same mode of action within a season and across years. Fungicides are categorized by their mode of action and assigned a FRAC (Fungicide Resistance Action Committee) grouping number. “Mode of action” refers to the molecular or functional mechanism by which the chemical works against the pathogen. In general, each FRAC code distinguishes different groups of fungicides based on their mode of action.

The FRAC guidelines and MFPM guide can inform the vineyard manager on combinations of fungicides to be used in tandem, as well as incompatibilities of certain products (i.e. stylet oil should not be applied within 2 weeks of a sulfur or Captan application) and restrictions on the amount of product or number of times per season a fungicide should be used.

Looking forward to the winter

Cultural control practices are necessary in the winter and early spring to remove dead and infected plant tissue (on the vine and leaf litter on the ground) that would otherwise create new infections in the upcoming growing season. One advantage of grape growing is the annual removal of approximately 90% of plant tissues and the plasticity in selecting new, disease-free canes. Dried infected berries, called “mummies”, should be removed from the vineyard. In fact, all infected tissues should be removed and destroyed including diseased material from the vineyard floor when feasible. Retraining new cordons and trunks is one way to improve production over time by reducing the accumulation of diseases and damaged wood from winter injury.

The importance of sorting

The computer science adage “garbage in, garbage out” is a mantra that we should be sharing in the wine world. Grapes infected with rots, mildews, or are otherwise unsound (already fermenting) are going to contribute to a wine product that is also faulty. Ethyl acetate is a common wine fault that is easily detected by wine drinkers, so there is very little tolerance for this in the juice or must going into wine making. Experiments have shown that wine made from infected berries with powdery mildew could be distinguished due off aromas, flavors, and textures. These included flavors described as moldy, bitter, dusty, plastic, and rotten (Conterno et al. 2006). Sorting by hand is labor intensive, but can be accomplished in the field with proper training (even with volunteer staff) or on a sorting table after mechanical harvest.

CAUTION: Mention of a pesticide or use of a pesticide label is for educational purposes only. Always follow the pesticide label directions attached to the pesticide container you are using. Remember, the label is the law. Be sure that the plant you wish to treat is listed on the label of the pesticide you intend to use. Also be sure to observe the number of days between pesticide application and when you can harvest your crop.

Reference

Conterno, L., D. Gadoury, V. Gerbi, L. Rolle et al. (2006). Grape fungal infection and wine quality. New York Wine Industry Workshop. Available Online